Ethylene Oxide (EtO) sterilization is used for gas compatible devices of all types and configurations for both terminal sterilization as well as sterilization of reusable medical devices. EtO has been touted as one of the most effective and ideal sterilization methods – but which materials and devices are best suited to this process? We’ve got the answers for you, along with the hows and whys of EtO’s successful rise to become the most widely used medical device sterilization method.

EtO as the Ideal Sterilization Method

Many delicate devices experience damaging results when sterilized via moist heat or radiation. Early studies quickly revealed that heat and moisture-sensitive devices could not withstand such methods successfully or achieve reliable sterility assurance, which is how EtO came to be the valued solution used by so many sterilization professionals today. Additionally, EtO is the only sterilization method that can reliably penetrate interior chambers or two surfaces in contact with each other.

More than 50% of all medical devices are sterilized with EtO, which total more than 20 billion devices annually, according to the Advanced Medical Technology Association – and most surgeries utilize at least one device that has been sterilized using EtO.

Which Materials or Devices are Best for EtO?

Medical device manufacturers use a variety of materials in their medical devices, which may range from plastics to non-woven materials to metal. However, other methods of sterilization can actually melt non-woven materials and plastics. EtO is a good choice when such materials are present. Common medical devices that are best for EtO sterilization due to sensitive materials or interior chambers include:

- Fiberoptic endoscopes

- Surgical kits

- Catheters

- IV sets

- Plastic tubing

- Surgical telescopes

- Heart valves

- Electrical equipment

- Surgical staplers or drills

- Respirators

- Pacemakers

What Else Makes EtO the Ideal Sterilization Choice?

Many EtO sterilization runs are small batch, which results in a faster turnaround – something medical device manufacturers are often looking for and value. For those who have EtO environmental gas concerns, they can take comfort in the fact that small batch EtO sterilization uses a single gas canister, resulting in less gas needed for processing. Ultimately a very small percentage of gas gets released into the atmosphere.

Today a majority of manufacturers rely on multiple professional EtO resources to ensure an uninterrupted sterilization process for their medical devices. Due to the potential hazards EtO carries, there are strict guidelines to its use. Already some sterilization facilities have halted EtO production due to violations. It’s important to identify a reliable EtO resource who is complaint with all regulations, and also have a back-up resource to handle overflow and be available if your other resource has interruptions in service.

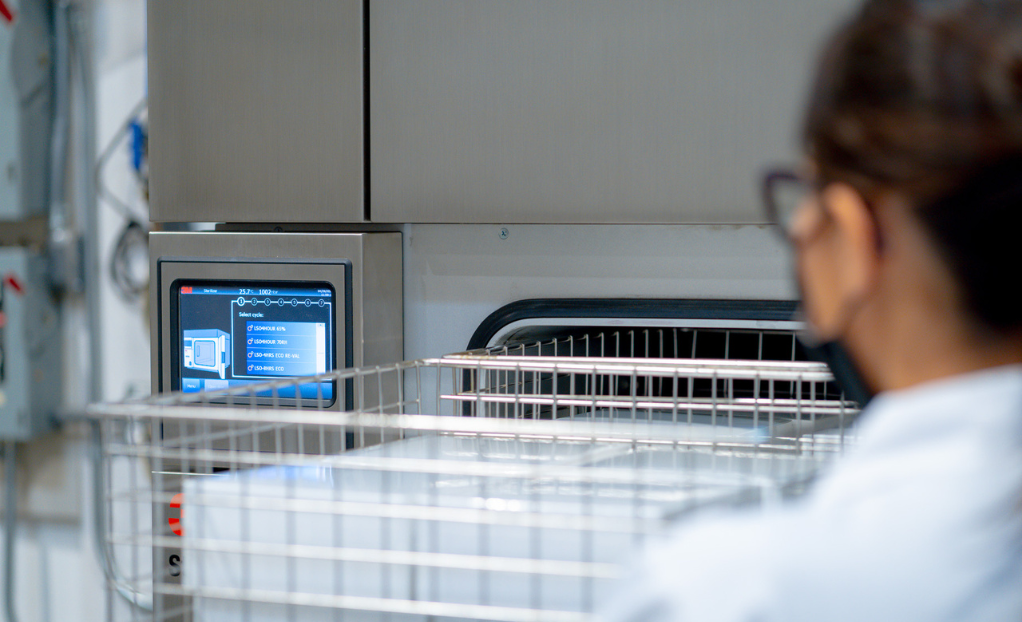

Life Science Outsourcing is uniquely positioned to support R&D, custom product, and lean manufacturing EtO cycles in our two in-house, 3M Steri-Vac™ sterilizers ~8 cubic feet, validated chambers. We also provide in-house BI testing. Contact us for more information on our EtO processes and how they can help you achieve faster turnaround for your medical devices. Email us at info@lso-inc.com or call (714) 672-1090 today to get started.

Looking for more information on EtO sterilization? Read Medical Device Ethylene Oxide Sterilization: Environmental and Technician Safety.