ASTM-F1140

Testing

ASTM F1140 testing is comprised of the following:

- Burst Test

Determines package strength by pressurizing a package until it bursts. - Creep Test

Determines package strength by pressurizing a package at a set percentage of the known burst pressure for a fixed amount of time.

Test Methods

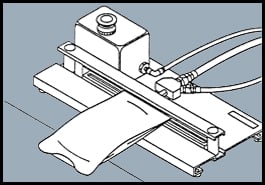

POSITION 1

Note 1: The sample is inserted in the test clamp and is left unsupported and untouched during testing.

POSITION 2

Note 2: The sample is inserted in the test clamp and is held firmly enough to keep the package horizontal, sealed and straight during inflation without putting undue pressure on the seal. This technique limits curling of the pouch, which may affect test results. This technique requires training for repeatability.

POSITION 2

Note 3: The sample is inserted in the test clamp and is left untouched during testing, but supported underneath.

In the Burst Test, air is introduced into the package at a predetermined pressure and flow rate. The porosity (or lack thereof) of the package material determines the inflation rate for the burst test. Because air escapes through the walls of a porous package during inflation, the flow rate must be increased to compensate for the lost air through the walls and create the back pressure in the porous package. This pressure creates the force needed to rupture the seal.

In the Creep Test, a whole package is inflated to a constant pressure, which is then held for a specified time, resulting in a pass / fail result. The Creep Test provides a test for slow shear of the adhesive bond similar to a dead weight hanging on the seal.