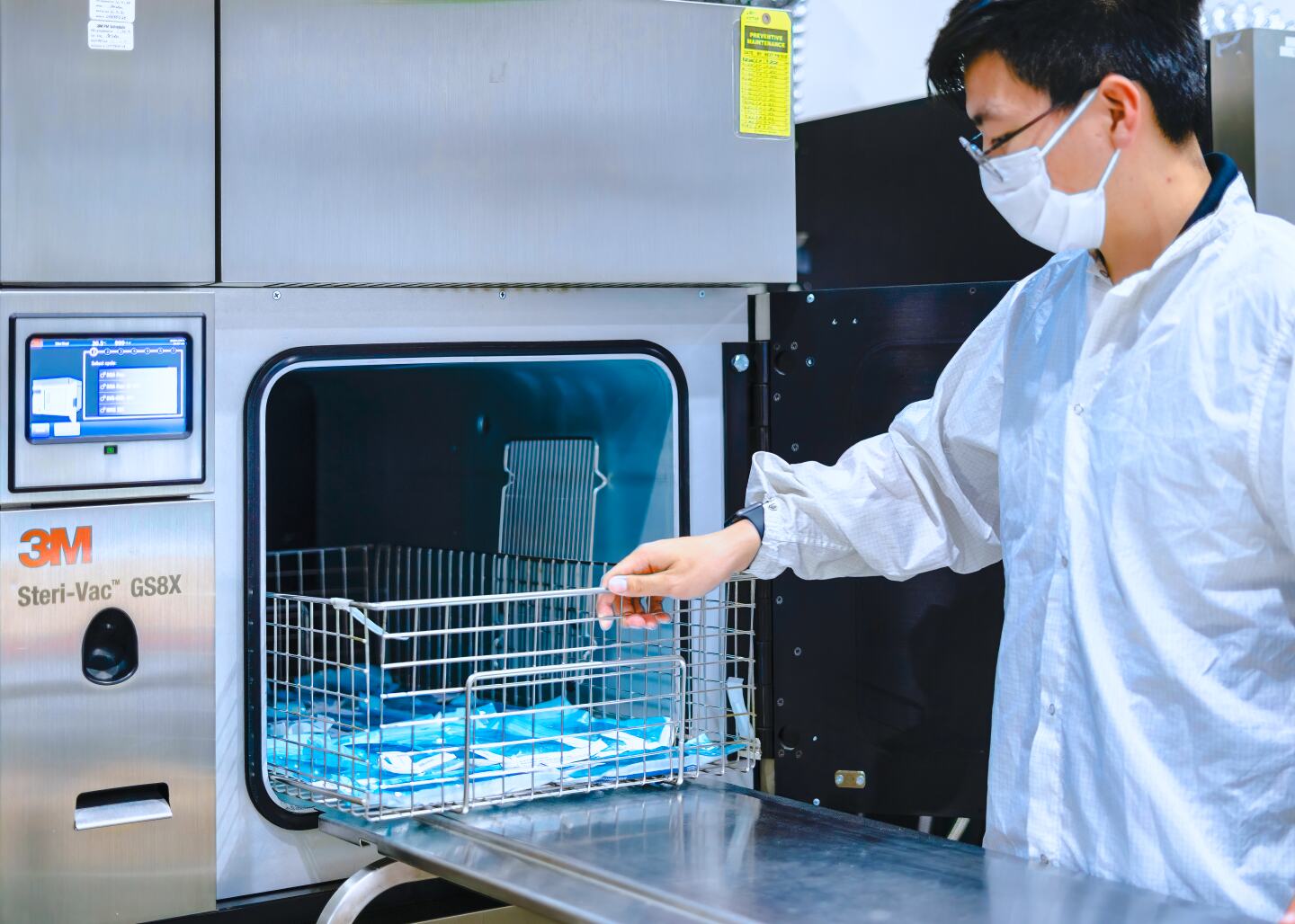

Ethylene oxide (EtO) sterilization is one of the most common methods used to sterilize medical devices, particularly those with heat- or moisture-sensitive components. But while EtO is highly effective at killing microorganisms, it also leaves behind chemical residues that can be harmful to patients if not properly removed.

That’s where EtO residual testing comes in. This critical test measures the levels of residual ethylene oxide and its byproducts—ethylene chlorohydrin (ECH) and ethylene glycol (EG)—on or in your device. The results determine whether your product is safe for patient use and compliant with global regulatory standards.

In this post, I’ll explain what EtO residual testing is, when it’s required, and how to determine whether your device needs it.

Learn more about EtO Residual Testing here: https://lso-inc.com/eo-residual-testing/

What Is EtO Residual Testing?

EtO residual testing quantifies the amount of residual ethylene oxide, ethylene chlorohydrin, and ethylene glycol remaining on a medical device after sterilization. These substances can be toxic, carcinogenic, or cause irritation if they exceed specified limits.

The testing is typically performed using gas chromatography and follows methods defined by ISO 10993-7. This standard outlines allowable limits based on patient exposure type and duration, such as limited (<24 hours), prolonged (24 hours to 30 days), or permanent (>30 days) contact.

Why Is EtO Residual Testing Required?

Regulatory bodies including the FDA and international agencies require EtO residual testing as part of sterilization validation and biocompatibility assessment. Even trace amounts of residual EtO or ECH can cause adverse reactions or toxicological effects in patients.

EtO residual testing is typically required:

- For all devices sterilized using ethylene oxide

- During initial sterilization validation

- As part of routine batch release for high-risk devices

- When changes to sterilization cycles, materials, or packaging occur

Failure to meet ISO 10993-7 limits can delay regulatory approval or result in product recalls.

When Should You Test for EtO Residuals?

EtO residual testing should be performed:

- During initial validation of your EtO sterilization cycle

- Any time you change your sterilization parameters (e.g., cycle time, temperature, aeration)

- When switching suppliers or materials

- As part of ongoing compliance for devices with extended patient contact

Testing is not a one-time event—it’s part of an ongoing control strategy to ensure product safety and regulatory alignment.

Final Thoughts

EtO residual testing ensures that your ethylene oxide sterilized medical device is safe for use and compliant with ISO 10993-7 and FDA requirements. Because patient safety and regulatory submissions depend on accurate chemical residue analysis, EtO residual testing should be a non-negotiable part of your sterilization validation strategy.

If you’re unsure whether EtO residual testing is required—or need to test for changes in sterilization cycles or materials—Life Science Outsourcing can help. Our in-house chemistry lab offers fast, GLP-compliant EtO residual testing backed by regulatory expertise.

Learn more about EtO Residual Testing here: https://lso-inc.com/eo-residual-testing/