When most people hear “resilient supply chain,” they think of backup suppliers. In orthopedics, resilience is more than redundancy. It’s the ability to keep devices compliant, audit-ready, and on schedule — even when disruptions hit.

Why Resilience Matters in Orthopedics

Orthopedic OEMs operate under intense scrutiny: recalls, audits, and shelf-life reliability leave no margin for error. A missed sterilization cycle or packaging delay can cost millions and damage trust.

COVID exposed just how fragile global supply chains could be — titanium shortages, sterilization bottlenecks, and stretched lead times left OEMs scrambling. That’s why resilience isn’t optional. It’s essential.

Beyond “More Suppliers”

Adding vendors doesn’t eliminate risk. In fact, more handoffs often create new weak points. True resilience comes from integration: aligning quality systems, logistics, and sterilization readiness under one roof to reduce risk and shorten timelines.

The LSO Approach

At Life Science Outsourcing, resilience means more than surviving disruption — it means preventing it:

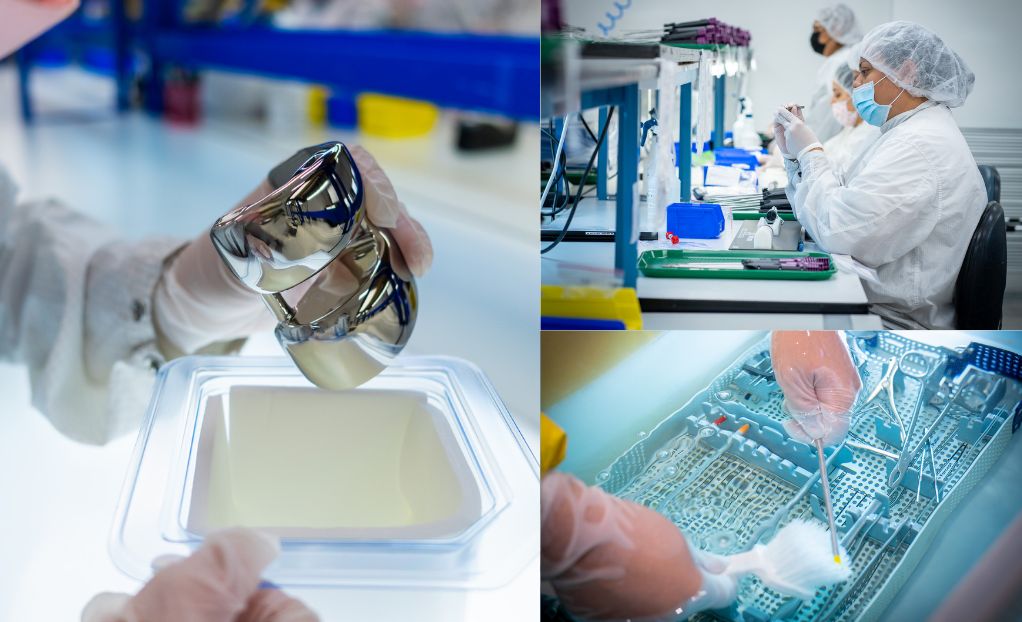

- Quality Integration: ISO 13485-certified processes from assembly through sterile packaging

- Sterilization Capacity: In-house services eliminate bottlenecks and delays

- Scalable Logistics: U.S. and Costa Rica facilities adapt to market fluctuations

This model keeps orthopedic OEMs compliant, repeatable, and reliable — even under pressure.

The Takeaway

Resilience in orthopedics isn’t about backups. It’s about designing a supply chain that withstands disruption without sacrificing compliance or delivery. That’s the LSO advantage.

Download Our Supply Chain Resilience Checklist

Want to know how resilient your orthopedic supply chain really is? Our checklist walks you through the critical areas of compliance, sterilization readiness, and logistics continuity that every OEM should evaluate.

With it, you’ll be able to:

- Identify hidden vulnerabilities in your supply chain

- Benchmark your audit and compliance readiness

- Prioritize next steps to strengthen resilience before disruption strikes