ASTM D4169 Schedule J: Concentrated Impact (Forklift & Handling Impacts)

What Is ASTM D4169 Schedule J?

ASTM D4169 Schedule J evaluates a packaged product’s resistance to concentrated impact forces that occur during material handling operations. These impacts are most commonly associated with forklift tines, pallet jacks, clamp trucks, and rigid handling equipment contacting localized areas of the shipping container.

Unlike drop testing (Schedule A), Schedule J focuses on high-force, small-area impacts that can penetrate or compromise packaging without involving free-fall energy.

Where Schedule J Fits in ASTM D4169

Schedule J is typically applied within distribution cycles where:

- Forklift handling is expected

- Unit loads are frequently repositioned

- Packages may be contacted at mid-panel locations

- Lightweight or single wall corrugated containers are used

- The Edge Crush rating is less than 44

- The Mullen Burst rating is less than 275 PSI

This schedule is especially relevant for concentrated damage modes that may not appear during vibration, compression, or drop testing.

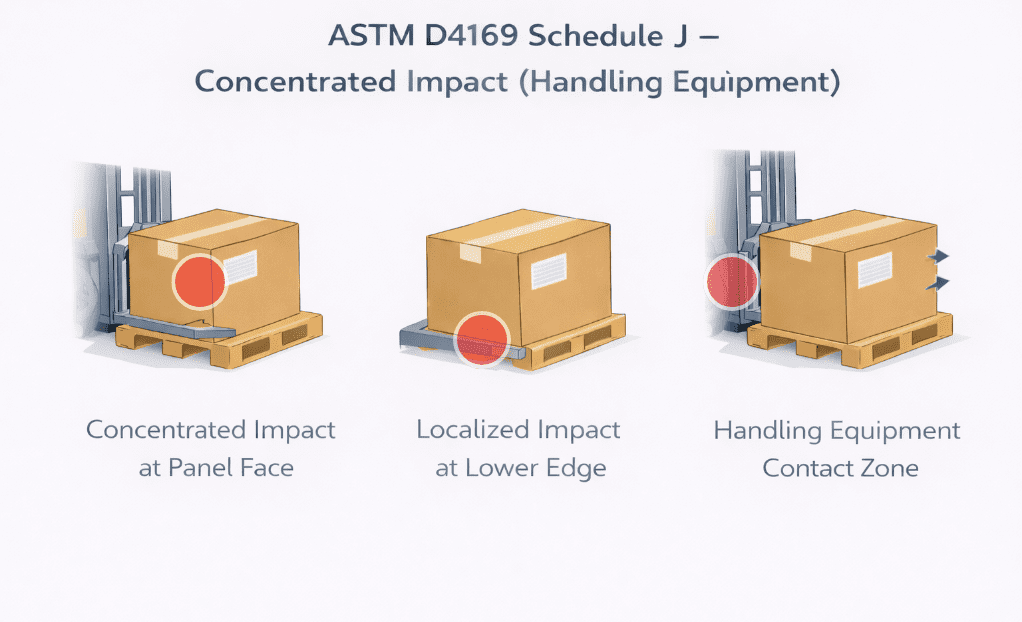

What Schedule J Simulates

Schedule J simulates impacts such as:

- Forklift tine strikes to carton panels

- Clamp truck contact points

- Pallet jack intrusion at lower box edges

- Rigid handling equipment contacting container surfaces

These events are localized and directional, producing damage that often bypasses cushioning systems entirely.

What Data Schedule J Produces

Schedule J produces visual and structural performance data related to packaging resistance at vulnerable contact points.

Key observations include:

- Panel puncture or fracture

- Corrugated flute collapse

- Permanent deformation at impact sites

- Breach of sterile barrier systems

- Loss of load containment or stability

Unlike schedules that evaluate cumulative damage, Schedule J focuses on single-event severity and failure thresholds.

How to Interpret Schedule J Results

-

Panel Integrity at Impact Zones

Damage at mid-panel locations may indicate:

- Insufficient board grade or flute profile

- Excessive unsupported span

- Misalignment between package design and handling reality

Panel failure during Schedule J often correlates strongly with real-world forklift damage.

-

Cushioning Bypass

Because Schedule J applies force externally and locally:

- Cushioning systems may provide little to no protection

- Damage can transmit directly to the product or sterile barrier

- Internal packaging may remain intact while outer containment fails

This distinction is critical when interpreting results.

-

Seal and Closure Vulnerability

If impacts occur near seals or closures, results may reveal:

- Seal delamination or tearing

- Increased risk of micro-leaks

- Localized stress concentrations not seen in drop testing

Schedule J is often followed by seal strength or integrity testing.

Common Misinterpretations of Schedule J

- Treating Schedule J as interchangeable with drop testing

- Assuming failure indicates poor cushioning performance

- Ignoring localized damage because overall package appears intact

- Evaluating results without considering forklift exposure frequency

Schedule J evaluates contact resilience, not overall package durability.

When Schedule J Is Most Valuable

Schedule J is especially valuable when:

- Forklift handling is unavoidable

- Cartons have a single wall or are lightweight

- Palletization creates exposed panel faces

- Field damage reports show punctures or tears

- Distribution environments are congested or fast-paced

- An excessive amount of headspace is found within the shipping container

Expert Insight

“Concentrated impacts don’t look dramatic, but they’re some of the most common causes of real-world package failures. Schedule J exposes weaknesses that drops and vibration simply won’t.”

— Matthew Emrick, Packaging & Distribution Testing Specialist

How Schedule J Supports Medical Device Packaging Validation

For medical device manufacturers, Schedule J helps demonstrate:

- Resistance to handling-induced container breaches

- Protection against localized sterile barrier compromise

- Alignment between package design and warehouse realities

When combined with other ASTM D4169 schedules, Schedule J ensures packaging systems are resilient against both environmental and human-induced hazards.

Summary

ASTM D4169 Schedule J evaluates a packaging system’s ability to withstand localized, high-force handling impacts common in real distribution environments. Its value lies in identifying vulnerabilities that occur without drops or vibration, providing essential insight into container robustness and handling compatibility.