ASTM D4169 Schedule E: Random Vibration (Vehicle Vibration Simulation)

What Is ASTM D4169 Schedule E?

ASTM D4169 Schedule E evaluates a packaged product’s ability to withstand random vibration encountered during vehicle transportation. Unlike fixed-frequency vibration tests, Schedule E uses random vibration profiles to more realistically simulate the dynamic, multi-frequency energy produced by trucksrailcars, and air transport.Schedule E is most commonly applied when validating packaging for truck and air distribution. The profiles simulate real-world data where long-duration vibration can lead to product movement, cushioning fatigue, seal stress, and progressive damage that may not be apparent after short vibration durations.

Where Schedule E Fits in ASTM D4169

Schedule E is typically performed after loose load vibration (Schedule F) or low pressure-high altitudes (Schedule I) and before or after other hazard simulations depending on the selected distribution cycle. Its purpose is not to create immediate catastrophic failure, but to expose cumulative damage mechanisms that occur over time.

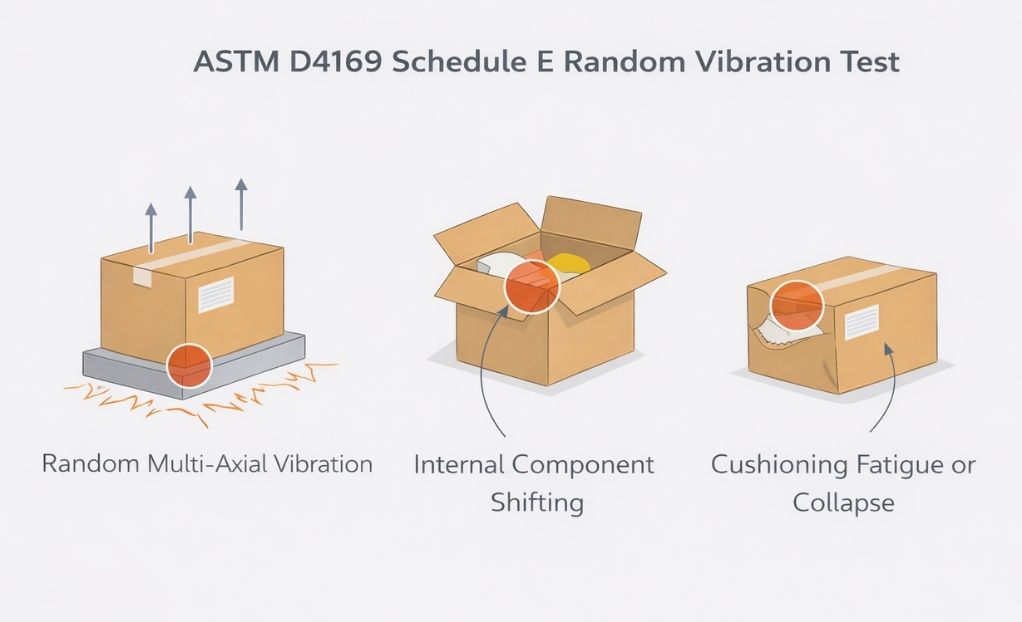

Schedule E addresses hazards that include:

- Vehicle-induced vibration

- Load shifting within the package

- Progressive weakening of cushioning systems

- Seal and closure fatigue due to repeated motion

What Data Schedule E Produces

Schedule E generates qualitative and quantitative observations related to how a package responds to sustained vibration exposure.

Key data and outcomes include:

- Evidence of internal product movement or migration

- Cushioning compression set or collapse

- Abrasion or wear at contact points

- Changes in package geometry (panel deformation, loss of squareness)

- Seal stress indicators (wrinkling, whitening, micro-tears)

- Audible changes during vibration indicating looseness or shifting

While Schedule E does not produce a single pass/fail numeric value, it provides critical contextual performance data that informs package robustness.

How Random Vibration Differs from Fixed Vibration

Random vibration testing applies energy across a range of frequencies simultaneously, reflecting real transportation conditions more accurately than fixed vibration.

Key distinctions:

- Random vibration simulates multiple vehicle inputs at once

- Whereas fixed vibration applies a single frequency for a defined duration

- Random profiles are statistically derived from field measurements

- Damage mechanisms tend to be cumulative rather than instantaneous

This makes Schedule E particularly valuable for identifying “failures” that occur only after prolonged exposure.

How to Interpret Schedule E Results

- Internal Component Shifting

If product movement is observed after testing, interpretation should focus on:

- Adequacy of internal retention features

- Cushioning resilience under cyclic loading

- Tolerance stack-up between product and packaging

Minor movement may be acceptable depending on product sensitivity, but repeated migration is a warning sign.

- Cushioning Fatigue or Collapse

Compression set, cracking, or permanent deformation of cushioning materials indicates:

- Material selection may be inadequate for vibration environments

- Cushion thickness or density may need adjustment

- Long-term distribution durability may be compromised

This is one of the most common stresses identified by Schedule E.

- Seal and Closure Stress

Random vibration can induce micro-movement at seal interfaces, leading to:

- Seal creep or whitening

- Increased peel variability

- Risk of micro-channel formation over time

These observations often trigger follow-up seal strength or integrity testing.

- Package Geometry Changes

Loss of squareness or panel bowing may indicate:

- Insufficient board strength for the selected assurance level

- Overly aggressive compression assumptions upstream

- Risk of pallet instability during shipment

Common Misinterpretations of Schedule E

- Assuming no visible damage equals acceptable performance

- Ignoring minor internal movement that may compound downstream

- Treating Schedule E as interchangeable with fixed vibration tests

- Evaluating results without considering assurance level alignment to other tests

Schedule E is about trend detection and durability, not just obvious tape failure or shipping container edge deterioration.

When Schedule E Is Most Valuable

Schedule E is particularly useful when:

- Products are sensitive to vibration-induced fatigue

- Cushioning systems rely on elastic recovery

- Long-duration ground transport is expected

- Early design iterations need durability insight

- Investigating field damage with no obvious drop events

Expert Insight

“Random vibration doesn’t usually cause immediate failure — it reveals how packaging systems degrade over time. Schedule E helps identify weaknesses that only show up after hours of sustained motion.”

— Matthew Emrick, Packaging & Distribution Testing Specialist

How Schedule E Supports Medical Device Packaging Validation

For medical device manufacturers, Schedule E helps demonstrate:

- Packaging durability during realistic transportation conditions

- Maintenance of protective features throughout distribution

- Reduced risk of latent damage affecting sterility or functionality

When combined with other ASTM D4169 schedules, Schedule E provides critical evidence that packaging performance is not just robust, but durable also.

Summary

ASTM D4169 Schedule E focuses on vehicle vibration realism, exposing packaging systems to sustained, multi-frequency motion that mirrors real-world transportation. Interpreting results requires attention to cumulative effects, assurance level alignment, and subtle indicators of degradation.

When used correctly, Schedule E delivers insight that short-duration or fixed vibration tests simply cannot.