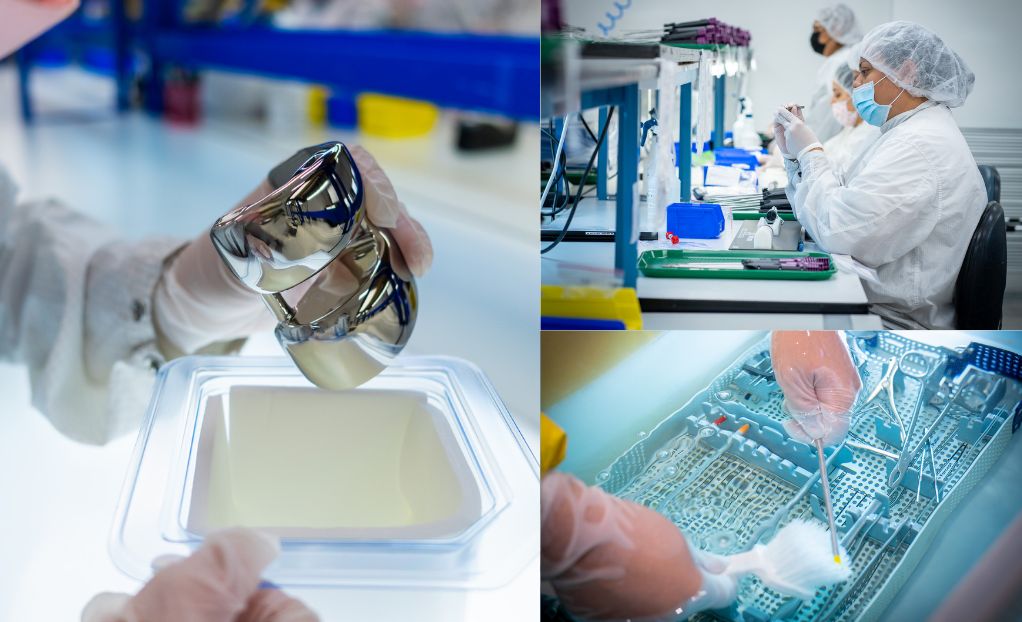

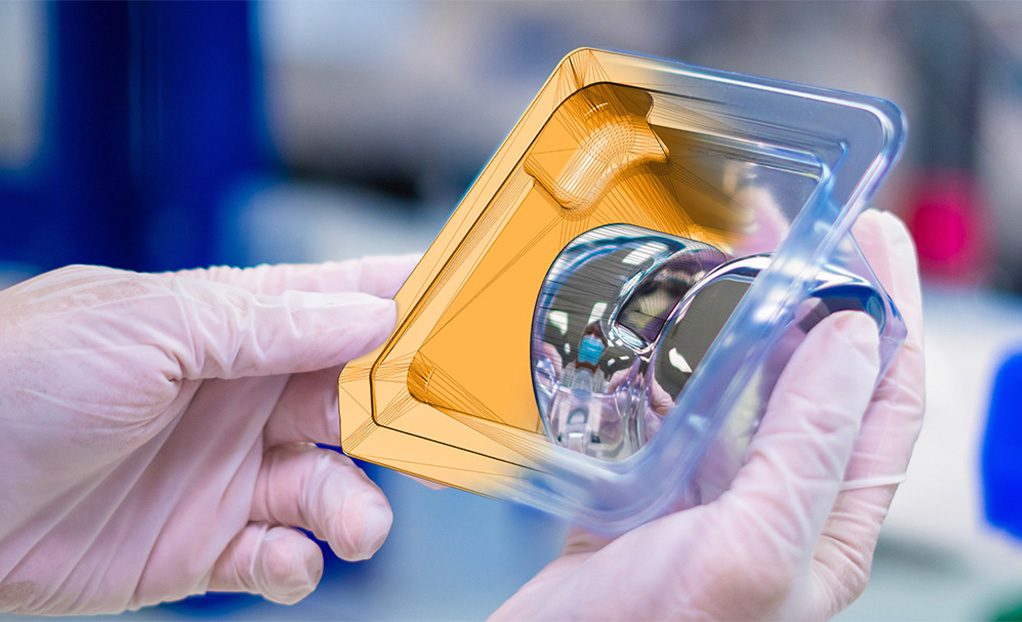

When the phrase “resilient supply chain” comes up, most people think about having a backup supplier or a secondary logistics partner on call. But in orthopedics, resilience runs deeper. It’s not just about building redundancies — it’s about ensuring that every implant, instrument, and kit makes it to market with compliance, repeatability, and reliability intact, no matter what disruption comes next.