Interpreting ASTM D4169 Schedule F: What Fixed Vibration Data Really Tells You

ASTM D4169 Schedule F is often misunderstood because it represents one of the more controlled—and frequently debated—vibration exposures within the standard. While sometimes viewed as less representative than random vibration testing, Schedule F plays a specific and intentional role in evaluating how packaging systems respond to repetitive, uniform vibration inputs.

For medical device manufacturers, the value of Schedule F lies not in simulating every real-world condition, but in isolating how a packaging system behaves under sustained, predictable vibratory stress and what that behavior reveals about design margins and risk.

What ASTM D4169 Schedule F Is Designed to Simulate

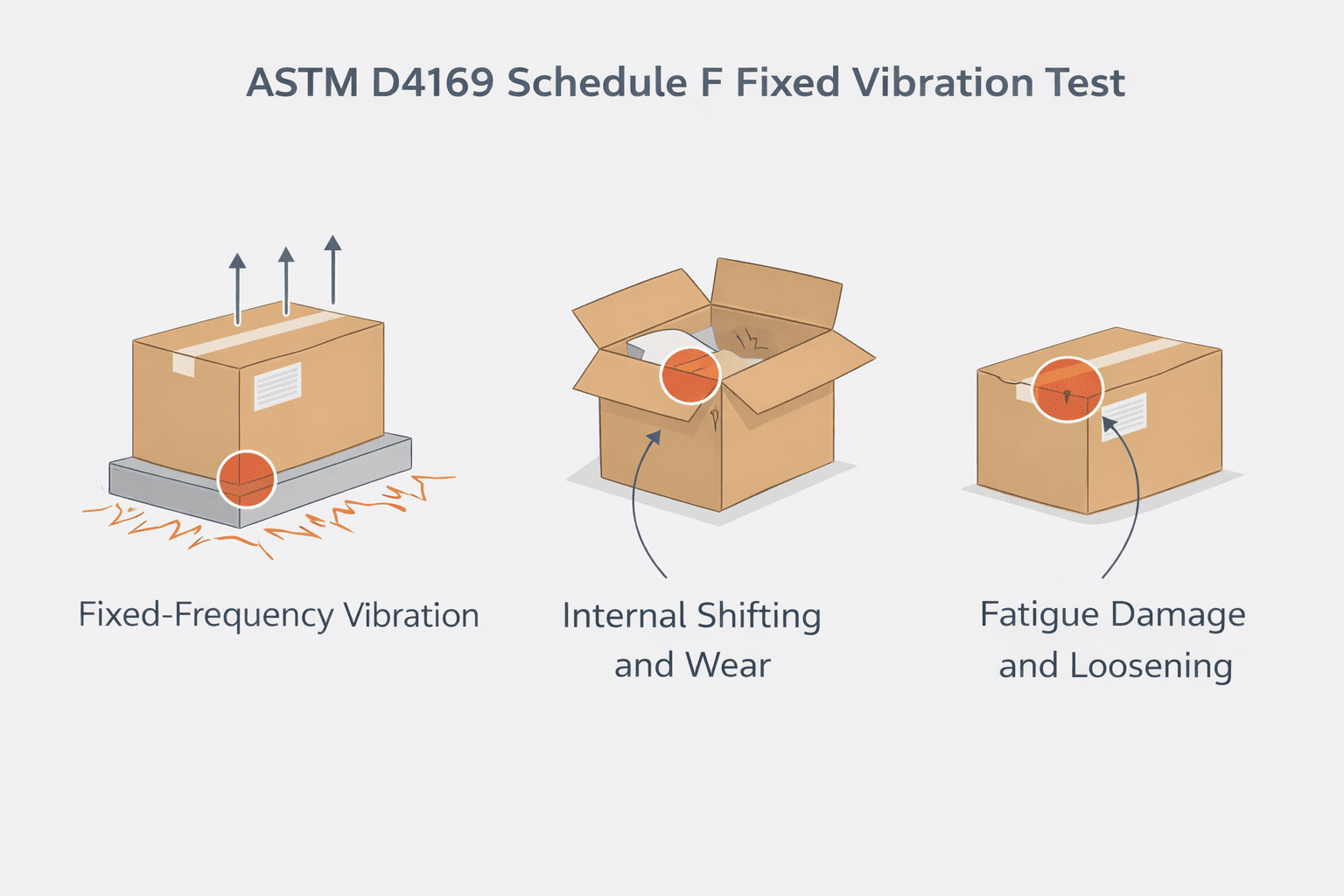

Schedule F represents fixed-frequency vibration associated with loose-load transportation environments. Rather than reproducing the full complexity of transportation vibration, it applies a consistent vibratory input intended to stress packaging components repeatedly over time.

Typical conditions represented by Schedule F include:

- Uniform vibration from vehicle motion

- Repetitive excitation at specific frequencies

- Sustained oscillatory inputs acting on the package structure

- Conditions where energy is concentrated rather than broadband

Schedule F is intentionally controlled. Its purpose is not to replicate every transportation scenario, but to expose packaging systems to repeatable vibratory stress that can reveal weaknesses not always apparent in handling or compression tests.

What Data Schedule F Actually Produces

Schedule F produces observational and performance-based data related to how a package responds to repeated vibration at a defined frequency.

Common observations include:

- Migration or shifting of internal components

- Abrasion between package elements

- Progressive loosening of closures or seals

- Fatigue-related material or seal damage

- Wear patterns at contact points

- Changes in package geometry after exposure

Unlike drop or compression testing, Schedule F rarely produces sudden, obvious failures. Instead, it reveals incremental degradation that may only become significant when combined with other distribution hazards.

How to Interpret Schedule F Results Correctly

- Repetition Matters More Than Severity

The defining characteristic of Schedule F is repetition. Even moderate vibration levels can cause meaningful damage when applied continuously.

Engineers should focus on:

- Whether damage accumulates progressively

- Whether wear patterns repeat across samples

- Whether internal movement increases over time

A lack of catastrophic failure does not imply low risk.

- Look for Fatigue and Wear, Not Just Breakage

Schedule F is particularly effective at exposing:

- Abrasion between components

- Fretting at interfaces

- Gradual loosening of seals, tape, or closures

These forms of damage often go unnoticed until downstream testing or field use.

Engineering perspective:

Damage that develops slowly under vibration is often harder to diagnose later, making Schedule F a valuable early indicator.

- Interpret Results in the Context of Other Hazards

Schedule F should not be interpreted in isolation. Engineers should evaluate whether vibration exposure:

- Reduces resistance to subsequent drops

- Increases susceptibility to compression damage

- Alters seal geometry prior to environmental testing

Vibration-induced fatigue frequently amplifies the effects of later test events.

Interpreting “Pass” Results Without Overconfidence

A common mistake is treating Schedule F as low risk simply because no obvious damage is observed.

Instead, engineers should ask:

- Did components move relative to one another?

- Did contact points show early wear?

- Did the package feel looser or less rigid after testing?

Subtle changes may indicate reduced design margin even when acceptance criteria are technically met.

Schedule F as a Diagnostic Tool

Schedule F is particularly useful for evaluating:

- Internal packaging stability

- Cushioning effectiveness over time

- Interface durability between materials

- Retention methods for devices and accessories

It is often used to identify design refinements rather than to demonstrate final distribution robustness.

Common Misinterpretations of Schedule F

Schedule F is frequently misused or misunderstood when teams:

- Treat it as a substitute for random vibration testing

- Dismiss results because vibration feels “too controlled”

- Ignore gradual wear or fatigue indicators

- Assume low severity equates to low risk

Schedule F is not intended to replace other vibration tests, but to complement them by exposing different failure mechanisms.

How Auditors and Regulators View Schedule F Data

Auditors and regulators generally view Schedule F as:

- Supporting evidence of vibration resistance

- A controlled method for identifying fatigue risks

- Part of a broader distribution validation strategy

They expect:

- Clear documentation of observed wear or movement

- Logical interpretation tied to risk

- Consistency with downstream test outcomes

Schedule F data becomes problematic only when it is used to justify conclusions beyond its intended scope.

Schedule F and Packaging Assurance Level

In medical device packaging validation, assurance level reflects confidence that a system will maintain performance throughout distribution based on the combined evaluation of multiple hazards.

ASTM D4169 Schedule F contributes to packaging assurance by evaluating how a package responds to repetitive vibratory stress that can lead to fatigue, wear, and gradual loss of integrity. The data helps identify latent weaknesses that may not appear during discrete handling or compression events.

Schedule F alone does not establish an overall assurance level. Its value lies in strengthening confidence when its results are interpreted alongside handling, compression, and other vibration exposures in alignment with ISO 11607 and risk management principles.

When Schedule F findings are well-documented and integrated with other test results, they reduce uncertainty and improve the defensibility of validation decisions.

Expert Perspective from LSO

“Schedule F is less about dramatic failures and more about what starts to wear down over time. When you see repeatable wear or movement after vibration, it’s telling you something about fatigue margins—even if nothing has technically failed yet.”

— Matthew Emrick, Packaging Specialist, Life Science Outsourcing

The Real Value of Schedule F

ASTM D4169 Schedule F is not designed to replicate every vibration environment. Its strength lies in its ability to expose incremental damage mechanisms that often go unnoticed until later stages of validation or field use.

When interpreted correctly, Schedule F:

- Identifies fatigue-related risks early

- Improves internal stability and retention design

- Strengthens overall distribution assurance

- Reduces late-stage validation surprises

Final Engineering Perspective

Schedule F should be viewed as a fatigue and durability lens within ASTM D4169. It does not replace random vibration testing, nor does it stand alone as a measure of distribution robustness.

Its true value emerges when teams use it to understand how vibration-induced wear interacts with handling, compression, and environmental exposures across the full distribution cycle.