When it comes to packaging validation, one standard is often treated as the make-or-break step: ASTM-D4332, the practice for conditioning packages before testing. And while it’s a critical part of the process, it’s not the whole story.

At Life Science Outsourcing (LSO), we’ve seen too many manufacturers treat ASTM D4332 environmental conditioning as the finish line, only to face delays, rework, and regulatory pushback later. The truth is simple: D4332 is only the beginning of a reliable packaging validation program.

What ASTM D4332 Covers — and What It Doesn’t

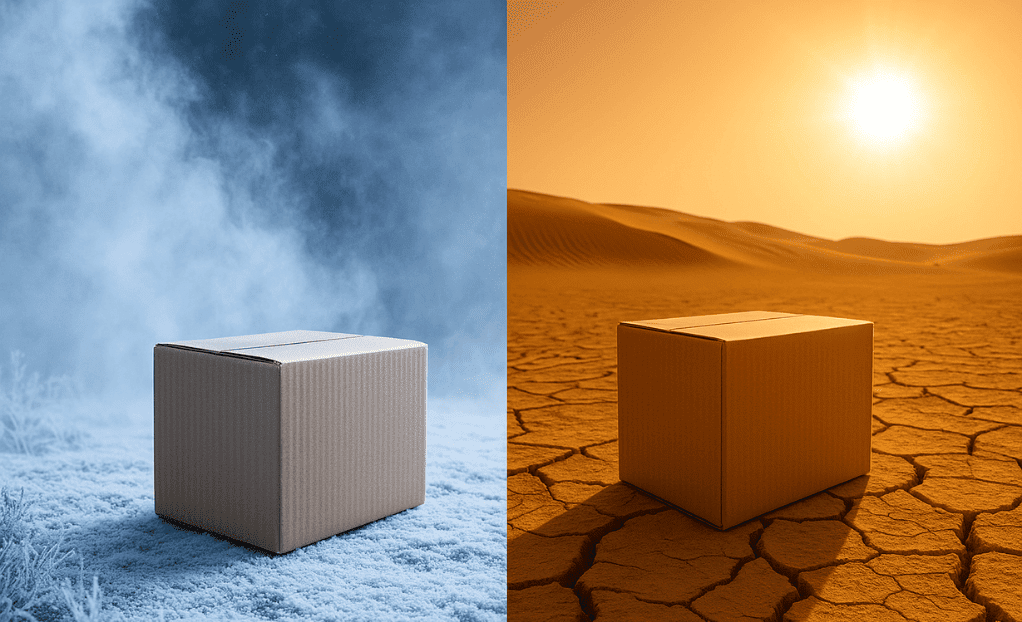

ASTM D4332 establishes temperature and humidity conditions that packages should be exposed to before distribution testing. Think of it as a way to simulate how your product packaging might respond to environments like cold-chain transport, tropical storage, or desert shipping.

It’s an important first step — but that’s exactly what it is: a step. Environmental conditioning doesn’t confirm whether your sterile barrier is intact, whether seals hold up through distribution, or whether packaging can withstand sterilization. For medical devices, diagnostics, and pharmaceutical products, those gaps can be costly.

The Missing Pieces of Packaging Validation

To achieve true regulatory defensibility, manufacturers need more than conditioning. A complete packaging validation program should include:

-

Sterile barrier integrity testing (ISO 11607): Proves that packaging maintains sterility through its lifecycle.

-

Distribution simulation testing (ASTM D4169): Confirms performance under real-world stresses like drops, vibration, and compression.

-

Seal strength testing (ASTM F88, F1929, F2096): Verifies that seals are strong, consistent, and leak-free.

-

Sterilization compatibility and validation: Ensures packaging holds up under steam, EO, or gamma sterilization without compromising product safety.

Without these components, ASTM D4332 results don’t tell the full story.

Why Integration Matters

Many manufacturers rely on separate vendors for packaging, sterilization, and testing. That fragmented approach increases the risk of:

-

Gaps in data and documentation.

-

Misaligned test parameters that don’t reflect the actual sterilization process.

-

Extra costs and time lost in vendor handoffs.

-

Regulatory findings that delay product launch.

At LSO, we eliminate those risks by integrating all the steps under one roof. That means your packaging is conditioned, tested, sterilized, and validated in a single, seamless workflow.

How LSO Goes Beyond ASTM D4332

Our one-stop model gives manufacturers an advantage that goes beyond lab results:

-

Smarter validation: We align ASTM D4332 with all downstream testing and sterilization, so nothing falls through the cracks.

-

Faster timelines: No vendor handoffs — just one partner moving your program from conditioning through sterilization.

-

Stronger regulatory readiness: As an FDA-registered, ISO 13485-certified, ISTA-certified organization, we support customers through audits with documentation that withstands scrutiny.

For over 25 years, LSO has helped medical device and diagnostic manufacturers bring safe, compliant products to market with confidence. Environmental conditioning is part of that journey — but it’s never the end.

The Bottom Line

ASTM D4332 matters. But if it’s the only box you check, your packaging validation is incomplete — and your regulatory position may be weaker than you think.

At LSO, we connect D4332 to the rest of the validation pathway, giving you smarter testing, faster turnaround, and stronger audit defensibility.