Decentralized healthcare delivery models have created an increased demand for a broader range of diagnostics tests to be closer to patients and provide comprehensive care. The need for versatile test delivery has skyrocketed as outpatient facilities expanded and more preventive and urgent care services become available at retail locations. Such diagnostic tests are often performed with reagents packaged in blister packs.

When it comes to ensuring their effective and reliable delivery to the point-of-care, microfluidic diagnostic products will require cartridge and reagent blister packs tailored to their precise filling and packaging needs. Reliable reagent packaging design, testing, process development and manufacturing is necessary for such diagnostic products to achieve safe commercial production and fulfillment. Unfortunately, some diagnostic companies that are developing new or enhanced point-of-care tests are confined to packaging platforms with inflexible options and strict throughput requirements that limit their ability to obtain ideal packaging outcomes. However, custom blister packaging solutions can overcome these roadblocks.

Custom reagent blister packs for diagnostic products

Custom microfluidic blister packaging offers many flexible advantages. A contract packaging partner in-house manufacturing team can assist you with creating a custom blister for your reagent, which can be formatted to fill size, shape, and dimensions. The two sections of a blister pack include a cavity section made of cold-formable aluminum-polymer laminates, and a lidding to seal your reagents into the package. The goal is to securely contain your reagent for superior stability and longevity.

Blister pack customization must follow certain specifications spanning:

- Blister pack fill volume

- Blister shape, size and other dimensional characteristics

- Microfluidic cartridge manufacturing

- Console actuating force

- Reagent blister pouch automation

- Quantity

When a customized blister pack approach is needed for your diagnostic product, you’ll want to consider the following five steps:

Predosed reagent blister pack testing and validation

Any reagent blister pack should provide safe storage for your predosed reagents. Testing and validation processes will ensure your reagents are protected and ready for use. Contract packaging resources such as Life Science Outsourcing (LSO) will inspect the fill volume, seal strength, and chemical stability using accelerated aging studies. These verify the reagent blister shelf life claims.

Reagent blister pack process development

The process development aspect includes reagent blister forming, filling, and sealing that should meet your specific product requirements. Your contract packaging partner should follow a design of experiments (DOE) approach to develop your process parameters.. To achieve this, they run a controlled set of tests that will model the interactions of specific factors and one or more responses. In short, they approach your process development with the specialized focus it deserves and requires.

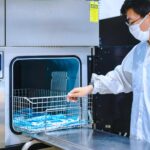

Production of your customized blister packs

Your ideal contract packaging partner should offer manual, semi-automated, or fully automated production of your diagnostic reagent blister packaging and microfluidic cartridges. This offers you and your product more adaptability in the long run. At LSO, our production process development uses full-scale forming, filling, and sealing technologies to assure high quality outcomes once the production phase begins.

Supply chain management

Successful supply chain requires an extensive network of suppliers. LSO has reliable materials sourcing and suppliers of standard and custom blister foils, lidding, and ISO-certified custom reagents to meet your packaging needs in an efficient and expedited manner.

Unique blister pack requirements

Reagents can be sensitive, requiring more intricate designs and solutions. Your contract packaging partner should be able to meet these demands and offer high-performing options. LSO has unique processing capabilities in areas of degassing reagents and 100% filling.

Custom reagent blister packs for successful commercialization

Don’t let your much-needed diagnostic products be sidelined by inflexible packaging platforms. If your diagnostic product requires a custom packaging approach, there is an answer in custom reagent blister packs. And the right contract packaging partner can help.

LSO supports diagnostic companies by providing reagent blister packs and microfluidic cartridge assembly ranging from a few thousand to tens of millions of units annually to ensure cost-effective commercial launches of innovative microfluidic diagnostic products. LSO offers in-house design capabilities, testing and validation, and manufacturing of custom blister packs for your products – from initial design prototyping all the way to commercial production.

Looking for more information on medical device packaging? Read Medical Device Manufacturing Must Evolve to Keep Pace with the Times.

Start up. Speed up. Scale up. Founded in 1997, Life Sciences Outsourcing is an FDA-registered and ISO 13485-certified organization with services and capabilities spanning the entire medical device product life-cycle – from turnkey manufacturing, testing, validation, and sterilization to precision packaging, fulfillment, and distribution. Email us at info@lso-inc.com or call (714) 672-1090 today to get started.