Medical device companies must deliver reliable products to market – without package failure. Reliable packaging and seals are critical to ensure much-needed devices arrive to their destination in a sterile state and ready to deliver on the promise of improving outcomes for physicians and their patients. To facilitate this end goal, packaging undergoes a rigorous testing process to determine seal integrity. Packaging and its contents are exposed to specific seal challenges in six different steps to provide assurance and security that a package is sealed properly, is leak-free and is also secure from outside contaminants.

Medical device packaging can fail for many reasons, but the primary culprit is the seal-sealing parameters. Other reasons include losing integrity during processing and the distribution phases. All manufacturers must use the validation process to comply with the ISO 11607 standard, which confirms a product and package system are conjoined effectively to perform safely and effectively at the hands of the end user. It is used to verify that package integrity can withstand processing, expected shelf life and handling.

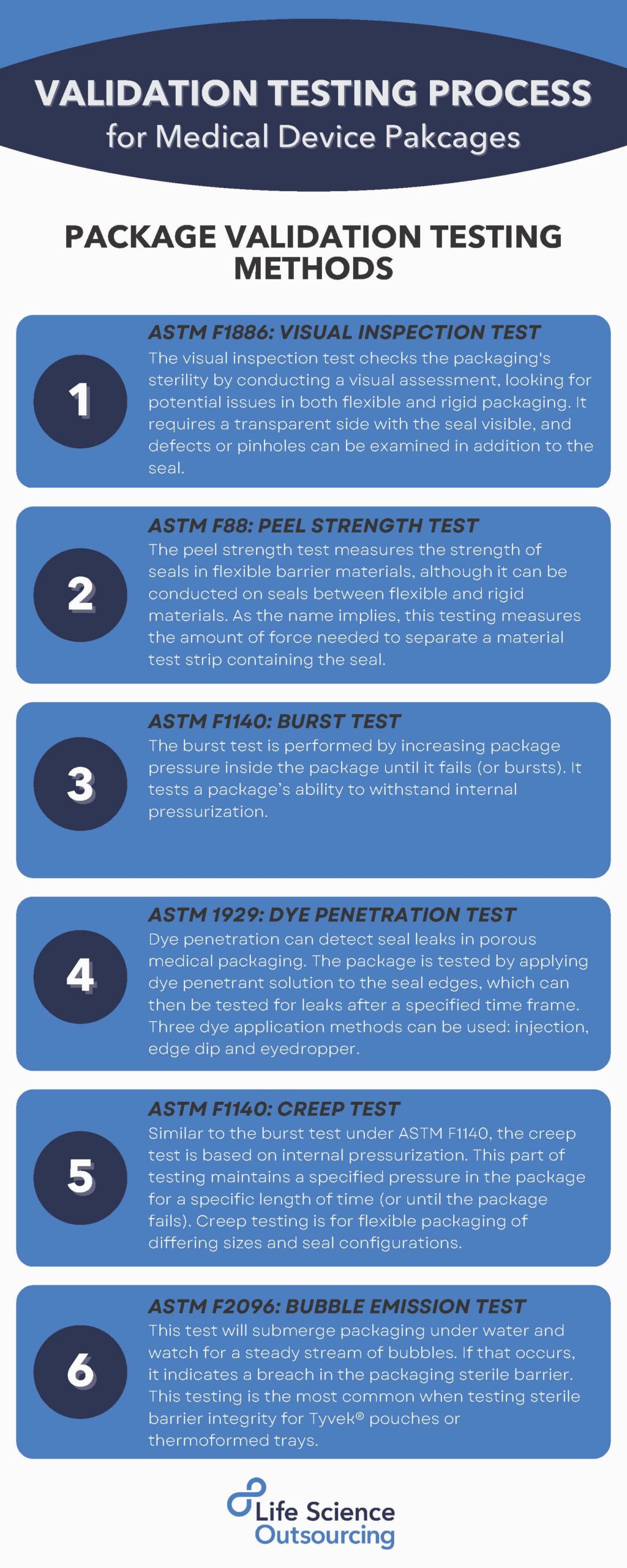

Package validation testing methods

The following are six package validation testing methods used to determine the integrity of medical device packaging and its seals. Each is performed and documented to meet standards and regulations. We’ve also outlined them in a helpful infographic for you to save for future reference.

- ATSM F1886: Visual inspection test

The visual inspection test checks packaging sterility by conducting a visual assessment. A technician will look for potential issues, visible to the naked eye, in both the flexible and the rigid packaging. This type of visual test requires that the packaging have a transparent side with the seal being visible, which also allows for examination of any other defects or pinholes in addition to the seal.

The peel strength test is used to measure seal strength in flexible barrier materials, although it can be conducted on seals between flexible and rigid materials as well. Just as the name implies, this testing method measures the amount of force that is needed to separate a material test strip containing the seal.

- ASTM F1140: Burst test

The burst test method tests a package’s ability to withstand internal pressurization. It is performed by increasing package pressure inside the package until it fails (and bursts – hence the name).

- ASTM 1929: Dye penetration test

Dye penetration testing can detect seal leaks in porous medical packaging. The package is tested by applying dye penetrant solution to the seal edges, which can then be tested for leaks after a specific amount of time has passed. There are three dye application methods that can be used: injection, edge dip, and eyedropper.

- ASTM F1140: Creep test

The creep test is based on internal pressurization, similar to the burst test listed above. This part of package testing maintains a specific pressure in the package for a set amount of time (or until the package fails). Creep testing is used for flexible packaging of differing sizes and seal configurations.

- ASTM F2096: Bubble emission test

The bubble emission test uses water, rather than internal pressure, to identify packing seal issues. Packaging is submerged underwater, and the technician will watch for any steady stream of bubbles. If that occurs, it is a sign of a breach in the packaging sterile barrier. This testing is most common when testing sterile barrier integrity for Tytvek® pouches or thermoformed trays.

Package validation testing is an important part of medical package testing and ensures your products arrive at their destination with an intact sterile barrier. Aligning with the right packaging partner can support your efforts to comply with regulations and get to market faster. Learn more about LSO’s medical package testing services, including package validation testing, to drive the successful outcomes of your medical devices to benefit your mission of improving healthcare for physicians and their patients.