ASTM-F1140

View complete services

Typical response within 1 business day.

15-minute consult with a steam specialist.

ASTM F1140 Burst and Creep Testing for Medical Device Packaging

ASTM F1140 defines the methods used to evaluate the strength and integrity of flexible medical packaging by applying internal pressurization until a seal or material failure occurs. Burst and creep tests help determine the weakest area of the packaging and what pressure is needed to expose the weakest area. The weakest area could be within the seal or surrounding material.

What ASTM F1140 Measures

ASTM F1140 evaluates:

- Seal strength

- Material resistance to internal pressure

- Weak points in flexible packaging

- Early failures caused by sealing parameters or material defects

Q: What is the purpose of F1140?

To measure how much pressure a package can tolerate before failing and locating where the failure occurred.

Test Methods

Burst Test

The package is inflated until it ruptures. This identifies:

- Seal uniformity issues

- Weak seals

- Material weak points

- Variability in sealing processes

Creep Test

The package is inflated to a set pressure and held for a specified time. This identifies:

- Slow seal failures

- Stress-induced weaknesses

- Material creep behavior

- Seal durability under constant load

Q: Which test should I choose?

Burst tests reveal maximum strength; creep tests measure sustained strength over time. Both provide useful information if package inflation is a concern within the sterilization or distribution processes.

How ASTM F1140 Testing Works

- Condition samples per ASTM D4332 or equivalent.

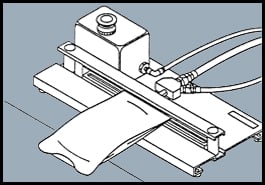

- Attach the flexible package to the burst/creep equipment so that it remains unrestrained.

- Apply internal pressure at a controlled rate.

- Record pressure at failure and location of the failure (burst) or time-to-failure (creep).

- Document results for statistical analysis and validation reporting.

Q: Is ASTM F1140 destructive?

Yes. Each package is pressurized to the point of failure.

Packaging Types Commonly Tested

ASTM F1140 applies to:

- Tyvek pouches

- Flexible sterile barrier systems

- Form-fill-seal pouches

- Laminated structures

Q: Can rigid trays be tested using F1140?

Trays are not the typical configuration to test with ASTM F1140. It can be used for trays but requires strong justification since the tray is not made of two flexible materials as the standard implies. Most trays consist of one semi-rigid to rigid material which is sealed with a flexible material.

ASTM F1140 Test Method Positions

POSITION 1

Description: The package is inserted into the test clamp and remains unsupported and untouched during inflation. This allows the material and seals to respond naturally to internal pressure.

Note 1: This position evaluates seal and material strength without external influence.

POSITION 2

Description: The package is clamped and held firmly enough to keep it horizontal, sealed, and straight during inflation without applying undue pressure to the seal. This technique reduces curling of the pouch, which can affect test results.

Note 2: Because operator handling influences repeatability, this position requires training and consistent technique.

POSITION 3

Description: The package is inserted into the test clamp and left untouched during testing, but supported underneath during inflation.

Note 3: Support helps maintain package geometry and can improve consistency across samples.

In the Burst Test, air is introduced into the package at a predetermined pressure and flow rate. The porosity (or lack thereof) of the package material determines the inflation rate for the burst test. Because air escapes through the walls of a porous package during inflation, the flow rate must be increased to compensate for the lost air through the walls and create the back pressure in the porous package. This pressure creates the force needed to rupture the seal.

In the Creep Test, a whole package is inflated to a constant pressure, which is then held for a specified time, resulting in a pass / fail result. The Creep Test provides a test for slow shear of the adhesive bond similar to a dead weight hanging on the seal.

ASTM F1140 vs ASTM F88

| Method | Measures | Best For |

|---|---|---|

| ASTM F1140 | Seal strength under internal pressure | Confirming real-world pressure tolerance |

| ASTM F88 | Mechanical peel force | Evaluating seal uniformity and sealing process performance |

Q: Do I need both tests?

If a burst test is performed, it usually supports the seal strength test like ASTM F88.

ASTM F1140 FAQ

What does ASTM F1140 measure?

Internal pressurization resistance of flexible sterile packaging.

What is the difference between burst and creep?

Burst measures maximum strength; creep measures strength over time.

Is the test destructive?

Yes, the package is inflated until it fails.

Does ASTM F1140 support ISO 11607 validation?

Yes. It is accepted for seal strength and sterile barrier verification.

What packaging types are compatible?

Any flexible sterile barrier system that can be internally pressurized.

ASTM F

All Standards

View complete services

Typical response within 1 business day.

15-minute consult with a steam specialist.