ISTA Standard 2A

ISTA 2A Testing for Medical Device Packaging

ISTA Procedure 2A is a general simulation test designed to evaluate the performance of individually packaged products weighing 150 lb (68 kg) or less. The procedure consists of a defined sequence of discrete hazard exposures intended to assess packaging durability during distribution.

ISTA 2A is commonly used for packaged products shipped through a variety of distribution systems and is applicable across a broad range of product types and packaging configurations.

What ISTA 2A Evaluates

- ISTA 2A evaluates how a packaged product responds to common distribution hazards, including:

- Vibration

- Shock events such as drops

- Compression

- Environmental conditioning (when specified)

Each hazard is applied as a separate, controlled test event rather than as a combined simulation.

Q: What is the primary purpose of ISTA 2A?

A: To evaluate packaging performance using a repeatable sequence of discrete distribution hazards.

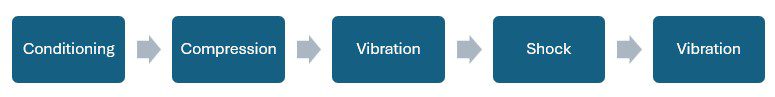

Structure of the ISTA 2A Test Sequence

ISTA 2A follows a defined, step-by-step procedure. While the exact sequence and conditions depend on the selected test profile, the standard generally includes:

- Atmospheric conditioning (when required)

- Compression testing

- Vibration testing

- Shock testing (drops)

- A second vibration sequence, which may replicate the first vibration exposure

The inclusion of multiple vibration sequences is an intentional part of the procedure and allows for extended exposure under controlled conditions.

Q: Why does ISTA 2A include more than one vibration sequence?

A: The procedure is structured to apply vibration as discrete events, which may be repeated to evaluate packaging performance under extended or repeated exposure.

| Sequence | Test Type | Standard | Description |

|---|---|---|---|

| 1 | Atmospheric preconditioning | ASTM D4332 | Ambient temperature and humidity |

| 2 | Atmospheric Conditioning | ASTM D4332 | Controlled Temperature and Humidity |

| 3 | Compression | ASTM D642 | Machine Apply and Release |

| 4 | Vibration | ASTM D999 orD4728 | Fixed Displacement or Random |

| 5 | Shock | ASTM D5276 | Drop |

| 6 | Vibration | ASTM D999 orD4728 | Fixed Displacement or Random |

Vibration Testing in ISTA 2A

ISTA 2A vibration testing typically uses random vibration, although fixed vibration is an option, to represent transportation-related motion. Unlike integrated simulations, vibration is applied as an independent test event.

Key characteristics include:

- Controlled vibration profiles

- Defined test durations

- Repeatable exposure conditions

This structure allows vibration performance to be evaluated independently from other hazards.

Q: Is vibration combined with compression in ISTA 2A?

A: No. Compression and vibration are applied as separate test events within the procedure.

Compression Testing in ISTA 2A

Compression testing in ISTA 2A evaluates a package’s ability to withstand stacking or top-load forces during distribution.

Compression is applied independently and may be based on:

- Calculated loads

- Predefined force levels

- Specified durations

This separation allows compression effects to be assessed without the influence of other hazards.

Q: What does compression testing evaluate?

A: The ability of a package to maintain integrity when subjected to stacking or vertical loads.

Shock (Drop) Testing

Shock testing in ISTA 2A consists of controlled drop events designed to represent handling-related impacts.

Drop testing may include:

- Specified drop heights

- Multiple orientations

- Defined impact surfaces

The goal is to evaluate how packaging protects the product during handling events.

Q: Are drop heights fixed in ISTA 2A?

A: Drop heights are defined by the standard and vary based on package weight.

Applicable Packaging Types

ISTA 2A may be applied to a wide range of individually packaged products, including:

- Medical device cartons

- Consumer and industrial packaged goods

- Flexible and rigid packaging systems

The procedure is applicable when the packaged product meets the weight and configuration criteria defined by the standard.

Q: Is ISTA 2A limited to medical devices?

A: No. ISTA 2A is a general distribution test and may be used for many packaged products.

Data Generated from ISTA 2A Testing

ISTA 2A produces data related to:

- Package deformation

- Product damage

- Seal or closure performance

- Package integrity following discrete hazard exposure

Results are evaluated against predefined acceptance criteria established by the test plan.

Q: Does ISTA 2A generate pass/fail results?

A: No, these tests are designed to expose packages to distribution hazards. How they fair against those hazards is determined using the data collected during the sequence of testing.

Relationship to Packaging Validation

ISTA 2A is often used as part of a broader packaging evaluation or validation strategy. The procedure provides structured, repeatable data that can support packaging performance assessments.

Q: Does ISTA 2A support ISO 11607 validation?

A: ISTA 2A may be used as part of a packaging validation strategy when appropriately justified and documented.

ISTA 2A FAQ

What is ISTA 2A?

A general simulation test for packaged products weighing 150 lb or less that evaluates packaging performance using discrete hazard exposures.

Does ISTA 2A simulate a specific distribution environment?

No. The procedure applies defined test events rather than replicating a specific distribution system.

Are hazards combined during testing?

No. Compression, vibration, and shock are applied as separate test events.

Is ISTA 2A destructive?

Testing may be destructive depending on the observed results and interpretation of the data resulting from the sequence of testing.

Talk to a Specialist About ISTA 2A Testing

Discuss how ISTA 2A fits within your overall packaging evaluation or validation approach.

ISTA Standards

All Standards