Interpreting ASTM D4169 Schedule C: What Compression Data Really Tells You

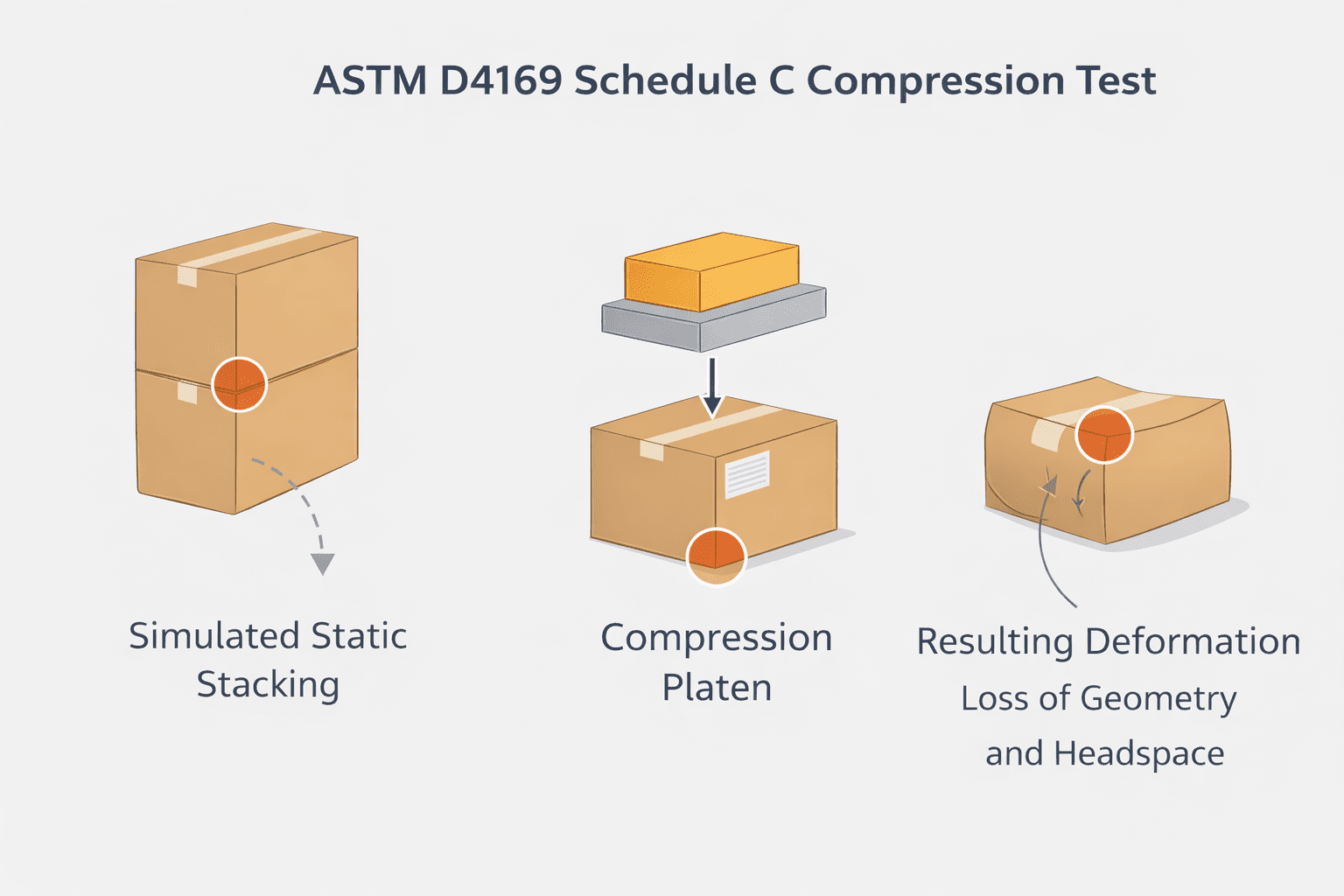

ASTM D4169 Schedule C is commonly described as a “compression test.” While accurate at a surface level, that description undersells the value of the data produced. Schedule C is not simply about whether a package collapses—it is about how a packaging system responds to sustained and stacking-related compressive loads, and what that response reveals about structural margins, load paths, and validation risk.

For medical device manufacturers, interpreting Schedule C data correctly is essential to understanding stacking risk, long-term deformation, and cumulative damage potential within a distribution environment.

What ASTM D4169 Schedule C Is Designed to Simulate

Schedule C represents compressive hazards encountered during distribution, including:

- Load transfer from palletized or unitized freight

- Long-duration compressive forces during transit

- Compression under restrained or semi-restrained conditions

Unlike Schedule A, which focuses on discrete handling events, Schedule C evaluates sustained load exposure over time. It is intended to simulate what happens when packages are stacked, constrained, or subjected to vertical loads that persist rather than dissipate.

Within distribution cycles such as DC-13, Schedule C typically represents the structural stress environment between handling and transportation events.

What Data Schedule C Actually Produces

Schedule C produces quantitative and observational compression response data that must be interpreted holistically.

Typical data outputs include:

- Maximum load sustained before deformation

- Permanent versus elastic deflection of packaging components

- Loss of package geometry or squareness

- Buckling or panel instability

- Sterile barrier system distortion due to package collapse

- Changes in internal clearances or headspace

- Post-compression ability to withstand downstream vibration or handling

The most important insight is not the applied load value itself, but how the packaging system distributes and absorbs that load.

How to Interpret Schedule C Results Correctly

- Permanent Deformation Is More Significant Than Peak Load

A common misinterpretation is to focus solely on the magnitude of the applied compressive load. Engineers should instead ask:

- Did the package recover its original shape?

- Was deformation elastic or permanent?

- Did load application change seal geometry or stress distribution?

Permanent deformation—even without visible failure—can compromise downstream performance and invalidate subsequent test results.

Engineering perspective:

A package that “holds the load” but does not recover may already be functionally weakened.

- Load Path Matters as Much as Load Magnitude

Schedule C often reveals whether compressive loads are being carried by:

- Intended structural features (e.g., inserts, corners, rails, stiffeners), or

- Unintended elements such as seals, sterile barriers, or device contact points

When loads transfer through seals or product interfaces, the risk to sterile barrier integrity and device protection increases significantly.

Repeated deformation in the same regions is a strong indicator of poor load path design.

- Compression Data Must Be Interpreted in Sequence Context

Schedule C rarely exists in isolation within a distribution cycle. Compression often precedes or follows:

- Vibration exposure

- Manual handling events

- Environmental conditioning or aging

Engineers should evaluate whether compression has:

- Reduced package stiffness

- Altered natural frequencies

- Increased susceptibility to vibration-induced damage

Compression damage can be cumulative and may not manifest as immediate failure.

Interpreting Failures Without Overreacting

Not all Schedule C “failures” require immediate redesign. Results should be interpreted through risk-based context, including:

- Impact on sterile barrier integrity

- Effect on device alignment or protection

- Changes to labeling or usability

- Potential regulatory or patient safety implications

The key question remains:

Does the observed compression response create a credible risk to package function, sterility, or validation integrity?

If the answer is no—and the rationale is documented—the outcome may still be acceptable.

Schedule C as a Structural Diagnostic Tool

Experienced packaging engineers use Schedule C to evaluate:

- Package stiffness and column strength

- Headspace allowances

- Material selection and thickness

- Reinforcement placement

- Palletization and stacking assumptions

Schedule C data is particularly valuable early in development, when structural changes are less costly and easier to implement.

Common Misinterpretations That Undermine Validation

Avoid these pitfalls:

- Treating Schedule C as a simple “stack height check”

- Using compression results alone to claim distribution robustness

- Ignoring permanent deformation that does not cause immediate failure

- Selecting unrealistically low loads to avoid deformation

- Repeating Schedule C without modifying package design or load assumptions

Repeated compression testing without change is not validation—it is data erosion.

How Auditors and Regulators View Schedule C Data

Regulators and auditors do not expect:

- Zero deformation

- Perfect package recovery

They do expect:

- Documented observations of deformation and recovery

- Logical interpretation tied to risk

- Justified load assumptions

- Alignment with ISO 11607 and ISO 14971 principles

A documented deformation with sound justification is often more defensible than an unexplained “pass.”

Expert Perspective from LSO

“Schedule C tells you how a package carries load over time. When compression shows up in seals or sterile barriers, it’s a signal that the structure isn’t doing the work it was supposed to do. That kind of data is invaluable early—because it’s much harder to fix once vibration and handling are layered on.”

— Matthew Emrick, Packaging Specialist, Life Science Outsourcing

The Real Value of Schedule C

Schedule C is not about proving that a package can withstand a single compressive force. It is about understanding how sustained loads affect structure, geometry, and downstream performance.

When interpreted correctly, Schedule C:

- Reduces late-stage validation risk

- Improves stacking and palletization decisions

- Strengthens structural design assumptions

- Supports defensible regulatory justification

Final Engineering Perspective

ASTM D4169 Schedule C is best viewed as a structural stress lens, not a simple pass/fail requirement. The data it produces is most valuable when interpreted in the context of load paths, deformation behavior, and how compression interacts with other distribution hazards.

When teams treat Schedule C as a learning tool rather than a checkbox, it consistently improves both packaging design and validation outcomes.