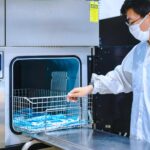

Life Science Outsourcing (LSO) is dedicated to enhancing customers’ operational efficiency by providing the latest and most advanced medical device manufacturing, packaging, and sterilization solutions. As part of our continued efficiency commitment, we are thrilled to announce the expansion of our ethylene oxide (EO) sterilization capacity. This expansion includes the addition of several 3M™ Steri-Vac™ GS8X Sterilizer/Aerator chambers at our facilities in California and New Hampshire.

This significant investment comprising three new chambers, effectively doubles LSO’s in-house sterilization capacity. Our goal is to expedite your supply chain while continuing to offer reliable sterilization compliance and procedures. We are excited to progress into 2024 with the installation, permitting, and validation of the new chambers. These developments will result in six exciting new benefits for our valued customers.

Key benefits of our expanded Services include:

- Increased capacity: For those with growing demands, our new sterilization chambers offer increased capacity without compromising quality. These expanded capabilities will allow for larger volume processing while maintaining the same high level of sterilization effectiveness.

- Faster turnaround times: This capacity boost translates into expedited processing of your medical devices and instruments.

- Enhanced local service: With facilities on both coasts, we are now even better positioned to provide reliable sterilization services at one of our locations closest to you.

- Integrated ecosystem enhancement: Our comprehensive ecosystems of services, spanning from design to commercialization, is now more robust. The increased sterilization capacity ensures more of your devices are efficiently processed under one roof, reducing supply chain risks and accelerating your market entry.

- Sustainable solutions: We are proud to introduce the latest pollution-reduction solutions that contribute to environmental sustainability and help you optimize operational costs.

- Customizable sterilization programs: We understand that every product family has unique needs. Our expanded range includes customizable sterilization programs, allowing you to tailor the solution to your specific requirements.

We understand that changes in our processes might prompt questions about service quality. Rest assured, our transition has been meticulously planned to ensure continuity and quality. Routine sterilization processes will remain unchanged. Sterilization of products will adhere strictly to the customer-approved equipment list, with additional sterilizers being qualified as necessary, backed by thorough validation and process equivalence studies. Our commitment to quality is unwavering, with stringent quality control measures in place.

LSO is a longstanding leader in sterilization services and an ISO 13485-certified contract manufacturer in both our California and New Hampshire facilities. We have a skilled team with long industry experience, including a principal microbiologist, validation engineer, and other experienced professionals. Aside from EO sterilization, we also offer more sterilization & validation solutions such as in-house steam sterilization and contracted gamma and e-beam services.

For more information on how our expanded sterilization services can benefit your business, we invite you to visit our website or contact our dedicated customer support team. Our experts are eager to provide detailed information, answer your queries, and help you select the ideal solution for your needs.