Medical device manufacturers must often anticipate developing custom packaging for the precise dimensions of a specific device and its delivery to market. The process can be lengthy and involves steps to ensure the design will meet industry standards and guidelines for protecting the device in transit while safeguarding its sterile barrier. But what if your device is a common size and shape? Pre-validated packaging solutions are a strategic option and were designed to expedite the packaging process, cut costs, and deliver your much-needed product to market faster than the custom packaging process would normally allow.

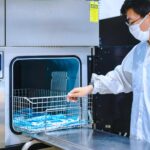

Pre-validated packaging configurations include trays with Tyvek lids and Tyvek/poly pouches. They have already passed necessary testing to protect a device and the sterile barrier, meaning they already have a validated sterile barrier system.

Medical device manufacturers can reap the following benefits by utilizing this simple solution and avoiding potentially costly customization delays.

Benefits of pre-validated packaging

The benefits of pre-validated packaging are many, including the fact that they have already been tested to meet standards and are quite literally ready to use right from the shelf.

Reduced costs

Pre-validated packaging can significantly lower upfront packaging development costs by eliminating the need for costly tooling and design fees. They are often immediately available as is and straight off the shelf, which eliminates added processing time and common expenses of custom-made packaging that could increase your end costs.

Expedited time to market

An enormous advantage to pre-validated packaging is that the pre-work has already been completed. It has undergone extensive testing and validation to meet regulatory requirements and protect the medical device and its sterile barrier. The lengthy validation process of packaging is not necessary – time to deliver products to market is therefore significantly reduced. It is estimated that pre-validated packaging can reduce a project timeline by almost a year.

Pre-determined regulatory compliance

Custom packaging requires a stringent design process to guarantee it meets all FDA and ISO industry standards and regulatory requirements. Having already undergone the necessary testing steps, pre-validated packaging reduces risk of regulatory issues or possible delays during the approval process.

Sterilization method compatibility

Medical device packaging must be designed to be compatible with certain sterilization methods. Pre-validated packaging has already been created with this in mind, often being compatible with multiple sterilization processes such as gamma irradiation, ethylene oxide (EtO), or electron beam (E-beam). Such an advantage provides incredible flexibility for manufacturers, as they can reduce their risk by using a proven product able to withstand sterilization processes and maintain sterility for a predetermined period. Life Science Outsourcing reviews the sterilization modality during the selection process to determine if pre-validated packaging is the best option for a specific product.

Standardized packaging options

Pre-validated packaging simplifies the package selection process with a variety of standardized sizes and configurations that do not require custom modifications. As such, they are suitable for a wide range of medical devices.

Reduced resource needs

In-house packaging expertise and resources are required to develop custom packaging options. However, they are not necessary for pre-validated packaging. This gives manufacturers more time to focus on core competencies and priorities, leading to potential cost savings and improved efficiencies.

Increased buying power

Pre-validated packaging is often available at lower prices due to economies of scale. Manufacturers may even be able to leverage their own buying power to negotiate even better pricing.

Pre-validated packaging may be an ideal solution for your medical device packaging needs, allowing you to reap the benefits to your bottom line. It not only offers a cost-effective, time-efficient and compliant solution for medical device manufacturers, but it also helps deliver products to market faster, elevating your healthcare impact and creating more time availability for your high priority strategies. Contact us today to learn more about our pre-validated packaging options. Or if your device requires custom packaging, we can help with that process too.

Looking for more information on medical device manufacturing? Read Tyvek: The Ideal Versatile Solution for Medical Device Packaging Needs.

Start up. Speed up. Scale up. Founded in 1997, Life Sciences Outsourcing is an FDA-registered and ISO 13485-certified organization with services and capabilities spanning the entire medical device product life-cycle – from turnkey manufacturing, testing, validation, and sterilization to precision packaging, fulfillment, and distribution. Email us at info@lso-inc.com or call (714) 672-1090 today to get started.