Medical packaging plays a crucial role in ensuring the safety and efficacy of medical devices. In the fast-paced world of medical devices, packaging has elevated its capabilities to meet increasingly stringent regulations to ensure ideal outcomes for patients and their providers. Medical device manufacturers can breathe a sigh of relief as one versatile solution has emerged with a way to satisfy regulatory demands and achieve necessary packaging outcomes with numerous benefits and unique properties. That solution is Tyvek®, which has become the preferred choice for medical device manufacturers and industry packaging professionals.

Benefits of Tyvek for medical devices

Tyvek was first developed by DuPont and is a 100% synthetic material made from high-density spunbound polyethylene fibers. The material was originally designed to meet demands in the construction industry but quickly became a favorite across other industries for its capabilities to resist tearing and water damage. It has become the material of choice for all medical device packaging over other plastics and paper. The following are what make Tyvek the ideal solution for your medical device packaging:

Sterilization compatibility

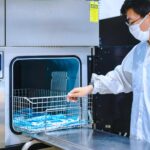

One primary reason for Tyvek’s popularity in the medical packaging industry is its compatibility with different sterilization methods. Its superior water resistance performance allows it to withstand moist conditions that most medical-grade papers cannot hold up to. Whether it’s ethylene oxide (EtO), gamma irradiation or electron beam sterilization, Tyvek can maintain its integrity and physical properties, ensuring that the packaged devices remain sterile and safe for use by the end user. Tyvek packaging sterility can be maintained for several years, as long as package integrity damage has not occurred.

Breathability and moisture control

Tyvek’s porous structure allows controlled permeability to air and moisture vapor. Vapor permeability is necessary to prevent rot and mold as moisture builds up on the interior packaging wall. This breathability feature is essential to maintain the sterility of medical devices by preventing the ability of microbes to get through, and facilitates the escape of excess moisture, preventing condensation buildup, and reducing the risk of microbial growth within the package itself. It strikes a delicate balance between keeping the package dry and allowing the necessary exchange of gases.

Microbial barrier

Tyvek acts as a formidable barrier against microbial contamination due to its dense and randomly arranged fibers. Its unique, porous structure creates a shield against microorganisms and prevents bacterial spore penetration, thus safeguarding medical devices from external contaminants. Such an effective microbial barrier is vital in maintaining the sterility and integrity of the medical device packaging.

Tear resistance

The exceptional tear- and puncture-proof resistance of Tyvek ensures that packaging remains intact during transportation, handling, and opening. It is also abrasive, water, UV, and chemical resistant as well. Even with slight damage, the packaging will not come apart. By minimizing accidental breaches, Tyvek helps to preserve the sterility of packaged medical devices, giving healthcare professionals and patients confidence in the device’s safety and effectiveness.

Lightweight and flexible

Tyvek is a lightweight material that can reduce shipping costs and make it easier to handle during packaging processes. Additionally, its flexibility and conformability allow it to adapt to various shapes and sizes of medical devices for ideal packaging configurations – and still offer an incredible strength-to-weight ratio. This versatility allows for efficient and customized packaging solutions.

Compatibility with adhesive sealing

Tyvek can easily be heat-sealed or adhesive-sealed to create a secure and reliable closure. This compatibility with different sealing methods ensures the integrity of the package, preventing microbial ingress and maintaining the sterile barrier. The ease of sealing also contributes to packaging operations efficiency.

Regulatory compliance

Tyvek meets the stringent regulatory requirements and standards of the medical industry, making it a trusted choice for medical device packaging. It has a proven track record of safety and permanence, having undergone extensive testing and validation for its intended use.

Tyvek maintains safety and efficacy of medical devices

When it comes to medical device packaging, Tyvek stands out as a versatile and reliable material. Its compatibility with various sterilization methods, breathability, microbial barrier properties, tear resistance, lightweight nature, flexibility, and regulatory compliance make it an ideal choice for ensuring the integrity and sterility of medical devices as they are transported, handled, and opened. As the medical device packaging industry continues to evolve, Tyvek remains at the forefront, playing a vital role in maintaining the safety and efficacy of medical devices throughout their lifecycle.

At Life Science Outsourcing, custom-developed packaging is specifically designed to fit your device, such as trays that securely hold the device or pouches with precise dimensions to snugly accommodate the device. We also offer pre-validated packaging configurations such as trays with Tyvek lids, Tyvek/poly pouches, header bags, and poly/poly bags.

Looking for more information on medical device packaging? Read Med Device Industry Trends: EtO Regulations, Sterilization Demand and Packaging Effiencies.

Start up. Speed up. Scale up. Founded in 1997, Life Sciences Outsourcing is an FDA-registered and ISO 13485-certified organization with services and capabilities spanning the entire medical device product life-cycle – from turnkey manufacturing, testing, validation, and sterilization to precision packaging, fulfillment, and distribution. Email us at info@lso-inc.com or call (714) 672-1090 today to get started.